If you’ve ever considered laser cutting for your project, you’ve probably wondered: just how precise is it? The short answer: very. But to really understand what laser cutting can (and can’t) do, we need to talk about tolerances – and don’t worry, we’ll keep this jargon-free.

What Do We Mean by “Tolerance”?

In manufacturing, tolerance simply means how much variation is allowed between the design and the finished part. No machine in the world is perfect – there will always be tiny differences – but the tighter the tolerance, the closer the result is to your exact design.

Think of it like this:

- If you draw a perfect circle, tolerance is how close the machine can cut to that circle’s true shape.

- A tight tolerance means almost no deviation.

- A looser tolerance means there’s a little more wiggle room.

How Accurate Is Laser Cutting?

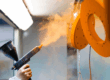

Modern laser cutting is one of the most precise methods available. At Foxy Lasers, our systems typically achieve:

- Cutting tolerances as tight as ±0.2 mm.

- Repeatability within ±0.1 mm, meaning part after part comes out consistently accurate.

This makes laser cutting ideal for projects where detail, accuracy, and consistency matter – from intricate prototypes to large production runs.

What Affects Laser Cutting Tolerances?

A few factors can influence the precision of a laser cut:

- Material Thickness – Thinner sheet metals are easier to cut with very tight tolerances, while thicker materials may have slightly more variation.

- Material Type – Mild steel, stainless steel, aluminium, and other metals all respond slightly differently to the laser beam.

- Machine Calibration – A well-maintained, high-quality laser (like ours) delivers sharper accuracy.

- Part Design – Very fine details, sharp corners, or extremely small holes may affect achievable tolerances.

Why Laser Cutting Is So Reliable

Compared to other cutting methods – like waterjet, plasma, or mechanical cutting – laser cutting stands out because it:

- Creates clean edges with minimal finishing needed.

- Offers repeatable accuracy even across high volumes.

- Reduces waste, since parts can be nested closely together.

In other words, it saves you time, cost, and hassle while delivering parts that look exactly as they should.

What This Means for Your Project

When you choose Foxy Lasers, you’re not just getting access to advanced machines – you’re getting a team that understands how to match tolerances to your project needs.

For decorative or structural parts, standard tolerances may be more than enough.

For precision engineering applications, we can advise on the tightest tolerances achievable with your chosen material and design.

We’ll always be honest about what’s possible, so you can have complete confidence in the final result.

The Bottom Line

Laser cutting is incredibly precise – often down to fractions of a millimetre. By understanding tolerances, you can design smarter, reduce costs, and ensure your parts are produced exactly as intended.

At Foxy Lasers, our in-house capabilities cover the full journey from laser cutting to bending, welding, and finishing – all with the accuracy and consistency your project deserves.

Got a design in mind? Send it our way and let’s see how precise we can get.